Precision is key in making maple syrup. A maple syrup hydrometer is a vital tool for producers aiming for top quality. It lets syrup makers measure liquid density accurately, ensuring each batch meets strict standards.

Both professional and hobbyist syrup producers see the hydrometer as a must-have. It helps them track sugar concentration and syrup quality. This ensures their maple products have consistent flavors that stand out.

The hydrometer offers a simple yet effective way to check syrup characteristics. It lets sugarmakers quickly see their syrup’s sugar content. This helps avoid problems during production and gives consumers a premium maple syrup experience.

Accurate density testing helps producers sort their syrup into different grades. This ranges from light golden to rich dark amber. Each measurement ensures the quality maple syrup lovers expect from their favorite natural sweetener.

Whether you’re a small-scale syrup enthusiast or run a big facility, knowing how to use a maple syrup hydrometer is key. The right equipment lets producers consistently make exceptional maple syrup. This captures the essence of this beloved natural sweetener.

Understanding the Importance of Maple Syrup Density Testing

Maple syrup production needs exact density measurements for quality control. The syrup’s density decides its grade, taste, and market value. Sugarmakers know that to make top-notch syrup, they must focus on every detail during production.

Density testing is key for grading syrup. It helps producers keep their syrup quality high. By measuring syrup density, they make sure their syrup meets strict standards and is of the best quality for customers.

Why Density Matters in Syrup Production

Getting the syrup’s density right is vital for quality:

- It shows how sweet the syrup is

- It tells if the syrup was boiled at the right temperature

- It ensures the syrup tastes right and is smooth

- It stops the syrup from going bad

Impact on Quality and Grading

The grading tool based on density affects syrup quality:

- It changes how dark the syrup is

- It affects the syrup’s taste

- It impacts the syrup’s health benefits

- It changes the syrup’s value in the market

Meeting Industry Standards

Producers of maple syrup use precise density tests to follow strict rules. Being consistent is essential for making maple syrup that meets customer needs.

“Density testing is not just a technical process, but an art form in maple syrup production.” – Vermont Maple Sugar Makers Association

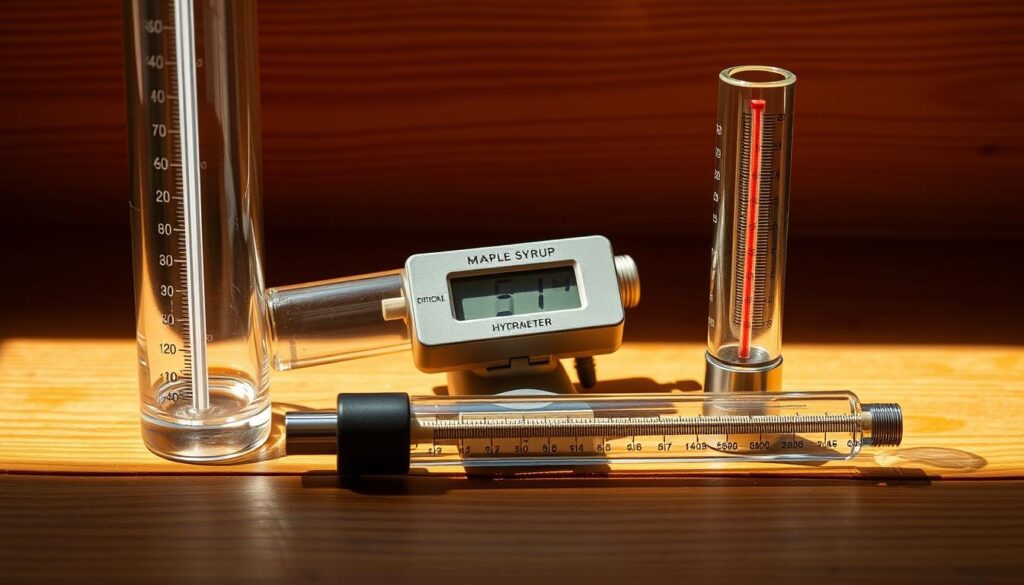

What is a Maple Syrup Hydrometer?

A maple syrup hydrometer is a tool used to measure the density and sugar content of maple syrup. It’s very precise. This tool is key for sugarmakers to keep their syrup quality high.

The hydrometer works by floating in the syrup. Its depth shows the sugar level. Made from glass or special materials, it gives important info on the syrup’s grade and value.

- Measures sugar density accurately

- Helps determine syrup quality

- Essential for professional maple syrup production

Professional sugarmakers use hydrometers to track sap to syrup. It’s based on a simple idea: as sugar levels go up, the hydrometer’s position changes. This lets producers see how the syrup is doing.

Key components of a maple syrup hydrometer include:

- Graduated scale for accurate readings

- Weighted bottom for stable floating

- Calibrated glass or plastic body

- Temperature compensation markings

Today’s maple syrup hydrometers are a big step up from old tools. They help sugarmakers make syrup that meets high standards. And it tastes great, just like what customers want.

How Does a Maple Syrup Hydrometer Work?

Maple syrup testing equipment is all about precision. A maple syrup hydrometer is key for measuring syrup density and sugar content. It does this with great accuracy.

The hydrometer works on the principle of buoyancy and specific gravity. It floats differently in various liquids. Sugarmakers use this to check their syrup’s sugar level.

Basic Operating Principles

A maple syrup hydrometer operates in a few ways:

- It measures liquid density by how deep it sinks

- It shows sugar concentration on a scale

- It gives precise readings based on its displacement

Reading and Interpreting Results

Reading maple syrup testing results needs attention. The hydrometer’s scale uses Brix or Baumé to show sugar content.

“Precision is the hallmark of exceptional maple syrup production.” – Maple Syrup Experts

Temperature Compensation Factors

Temperature affects hydrometer readings. Most hydrometers are set at 60°F. Sugarmakers must adjust for temperature changes to get accurate readings.

- Warmer temperatures make liquids expand

- Cooler temperatures make liquids denser

- Always measure at the same temperature

Knowing these principles helps maple syrup makers. They can keep their syrup quality high and meet strict standards.

Types of Hydrometers for Maple Syrup Testing

Choosing the right hydrometer for maple syrup testing is key for top-quality production. Different hydrometers have special benefits for sugarmakers who need precise density readings.

Maple syrup makers have many hydrometer options for accurate density tests:

- Traditional Glass Hydrometers

- Metal Hydrometers

- Digital Refractometers

- Specialized Maple Syrup Hydrometers

The best maple syrup hydrometer varies based on production needs and precision needs. Each type has its own advantages for syrup density measurement.

| Hydrometer Type | Accuracy | Price Range | Best For |

|---|---|---|---|

| Glass Hydrometers | Standard | $20-$50 | Small-scale producers |

| Metal Hydrometers | High | $50-$100 | Professional operations |

| Digital Refractometers | Precise | $100-$300 | Large commercial producers |

When picking a hydrometer for maple syrup, think about your budget, how often you’ll use it, and how precise you need it. Many professional sugarmakers use different types for thorough testing.

Digital hydrometers are the most advanced for maple syrup density tests. They give quick and accurate readings, better than traditional glass ones.

Digital vs Traditional Hydrometers: Making the Right Choice

Choosing the right tool for making maple syrup is key to quality and efficiency. The debate between digital and traditional hydrometers is important for those who want precise measurements.

Modern maple syrup makers face a big decision when picking a digital hydrometer. Each type has its own benefits that can affect how syrup is made.

Comparing Accuracy Levels

Accuracy is top of mind for maple syrup producers. Digital hydrometers usually offer:

- More precise measurements

- Instant digital readouts

- Enhanced temperature compensation

- Less chance of human error

Price Considerations

Buying a maple syrup tool means looking at costs over time. Traditional hydrometers are cheaper upfront. But digital ones might be more cost-effective in the long run because they:

- Last longer

- Need less maintenance

- Work more consistently

Ease of Use Factors

Sugarmakers need to think about how easy a hydrometer is to use. Digital hydrometers are often easier because they offer:

- Simplified reading processes

- Clear digital displays

- Automatic calibration

- Work well with record-keeping systems

The best choice depends on what you need, your budget, and how comfortable you are with technology. Both digital and traditional hydrometers can give reliable results if used right.

Essential Features of Quality Maple Syrup Testing Equipment

Choosing the right maple syrup testing equipment is key for top-notch production. Professional sugarmakers know that precise tools are vital for quality control.

When looking at maple syrup testing equipment, some features are must-haves for accurate readings:

- Durability of materials

- Precision measurement capabilities

- Temperature compensation mechanisms

- Ease of calibration

The best maple syrup testing instruments have advanced features. Digital hydrometers with thermometers give detailed data. This lets producers track small changes in syrup density.

Top-notch equipment usually has:

- Robust construction that stands up to maple syrup’s acidity

- Accurate readings from 0-100 Brix

- Fast response for quick measurements

- Automatic temperature adjustment

Investing in quality maple syrup testing equipment boosts production standards. The right tools ensure consistent quality. They also help make the syrup-making process better from start to finish.

Step-by-Step Guide to Using a Maple Syrup Hydrometer

Learning to use a maple syrup hydrometer is key for making top-notch maple syrup. This guide will show you how to use a hydrometer for syrup testing. You’ll learn how to get accurate density readings and make the best syrup.

Preparation Steps for Accurate Testing

Before you start, make sure you’re ready for precise results. Here’s what to do:

- Make sure the hydrometer and testing cylinder are clean and sanitized

- Let the syrup sample cool to the right temperature (usually 60°F)

- Get all your tools ready, including:

- A clean testing cylinder

- A maple syrup hydrometer

- A thermometer

- Clean cloth or paper towels

Detailed Testing Procedure

Testing with a maple syrup hydrometer needs focus and care:

- Pour the syrup into the clean testing cylinder

- Slowly put the hydrometer into the syrup

- Let the hydrometer float freely without touching the sides

- Read the density at the syrup’s surface

| Syrup Grade | Brix Reading | Density Range |

|---|---|---|

| Golden | 66-67% | 1.36-1.37 |

| Amber | 67-68% | 1.37-1.38 |

| Dark | 68-69% | 1.38-1.39 |

Cleaning and Maintenance Techniques

Keeping your maple syrup hydrometer in good shape is vital. Clean it and the testing cylinder with warm water and mild soap after each use. Stay away from harsh chemicals that could harm it.

Pro Tip: Always handle your hydrometer with care and store it in a protective case to prevent damage and maintain its precision.

Common Mistakes When Using a Syrup Hydrometer

Maple syrup testing needs precision and careful handling. Sugarmakers often face several common mistakes when using a maple syrup hydrometer. These mistakes can affect the accuracy of their measurements.

Experienced producers have found key mistakes that can ruin accurate density measurements. These errors can greatly affect syrup quality and grading:

- Using an improperly cleaned maple syrup hydrometer, which can introduce contamination

- Failing to allow sufficient time for temperature stabilization before testing

- Handling the testing equipment roughly, potentially causing damage

- Misreading the hydrometer’s scale due to eye-level alignment issues

Temperature is a big challenge in maple syrup testing. Improper temperature compensation can lead to inaccurate readings. This can cause syrup to be incorrectly classified or processed.

Precision is key when using maple syrup testing equipment. Sugarmakers should spend time learning about their hydrometer’s features and how to use it correctly.

- Always rinse and dry the hydrometer between tests

- Use a deep, clear vessel for accurate floating

- Check the hydrometer for any signs of damage before each use

- Calibrate equipment regularly to ensure consistent results

By avoiding these common mistakes, maple syrup producers can keep their quality and consistency high.

Professional Tips for Accurate Density Measurements

To get precise maple syrup quality control, you need to master density measurement. Sugarmakers know that getting accurate readings is key for consistent products and meeting standards. The right tool for measuring syrup density can greatly improve production quality.

For successful density testing, follow some key strategies. These methods help make maple syrup production more precise. Experts say to use a systematic approach that considers different environmental factors.

Essential Temperature Control Methods

Temperature is very important in density measurements. Here are some tips from experts:

- Use digital thermometers with 0.1-degree precision

- Create a stable testing environment away from heat sources

- Allow syrup samples to reach a consistent temperature before measurement

- Utilize water baths for precise temperature stabilization

Precision Calibration Techniques

Calibration is key for reliable maple syrup quality control. Sugarmakers should:

- Verify hydrometer accuracy using standardized reference solutions

- Perform regular calibration checks before each production cycle

- Document and track measurement variations

- Replace hydrometers every 2-3 years to maintain accuracy

Professional tip: Invest in high-quality maple syrup grading tools that offer consistent and reliable measurements.

Maintaining and Caring for Your Hydrometer

Keeping your maple syrup hydrometer in good shape is key for precise measurements. Sugarmakers put a lot of work into their craft. So, taking care of your equipment is vital for syrup quality.

To care for your maple syrup hydrometer, follow these steps:

- Clean it with distilled water after each use

- Store it in a case, away from sunlight

- Don’t expose it to sudden temperature changes

- Use clean, dry hands when handling it

It’s also important to regularly check your hydrometer for any issues. Look out for:

- Hairline cracks in the glass

- Mineral deposits

- Loose or damaged markings

- Signs of warping or bending

Remember, your hydrometer is a delicate tool for making maple syrup. With proper care, it can last for many years. This means you can make syrup with the perfect density every time.

Pro tip: Get a new hydrometer every 3-5 years or right away if you see any damage. This keeps your syrup-making accurate.

Troubleshooting Maple Syrup Density Issues

Maple syrup quality control is all about precise density measurements. Sugarmakers face challenges that can affect their syrup’s grade and value. It’s important to know how to solve these problems to keep syrup quality high.

Density issues can come from many factors in syrup making. Using a maple syrup grading tool helps producers spot and fix problems fast. This way, they can avoid ruining a whole batch.

Common Density Challenges in Syrup Production

- Over-concentration: When syrup gets too thick

- Under-concentration: Makes syrup watery and low quality

- Inconsistent temperature during testing

- Equipment calibration errors

Practical Solutions for Density Corrections

- Watch boiling temperatures closely

- Use precise quality control methods

- Regularly check and calibrate hydrometer equipment

- Adjust cooking times and heat levels

Experts say keeping testing conditions steady is key. Temperature is very important for accurate measurements. Even a small temperature change can affect readings and syrup quality.

Precision is the key to exceptional maple syrup production.

By using these troubleshooting tips, producers can reduce waste and keep syrup quality high.

Best Practices for Quality Control in Syrup Production

To keep maple syrup quality high, producers need a solid quality control plan. They must follow strict steps to meet both industry standards and customer needs. These steps are key to keeping maple syrup pure and delicious.

Effective maple syrup production involves several important steps:

- Regular calibration of density testing equipment

- Consistent temperature monitoring during production

- Detailed record-keeping of production parameters

- Strict hygiene and sanitization protocols

The sap-to-syrup conversion process needs to be precise. Producers must carefully watch the sugar content. They aim for a density of 66-67 Brix on their refractometers.

| Quality Control Parameter | Recommended Practice | Frequency |

|---|---|---|

| Density Testing | Use digital refractometer | Every batch |

| Temperature Monitoring | Consistent heat management | Continuous |

| Equipment Calibration | Professional instrument check | Quarterly |

Professional training is key to keeping quality high. Staff need to know the detailed steps of making maple syrup. Good training helps everyone work together to make a top-notch product.

Following these best practices helps maple syrup producers make a quality product. This meets the needs of both customers and industry standards.

Selecting the Right Hydrometer for Your Operation

Choosing the best maple syrup hydrometer is important. It depends on your production needs. Whether you make syrup for fun or sell it, the right tool can improve your syrup’s quality.

When buying a maple syrup hydrometer, think about a few things. How much syrup you make, your budget, and how accurate you need it are key. These factors will help you decide.

- Small-scale producers might look for affordable options

- Commercial operations need precise tools

- Hobbyists should find easy-to-use hydrometers

There are different hydrometers for different needs:

| Hydrometer Type | Best For | Price Range |

|---|---|---|

| Traditional Glass Hydrometer | Home Producers | $20-$50 |

| Digital Refractometer | Commercial Operations | $150-$500 |

| Specialized Maple Syrup Hydrometer | Professional Sugarmakers | $75-$250 |

Professional sugarmakers say get a good, accurate hydrometer. The right one keeps your syrup quality up and meets standards.

Think about what you need, your budget, and your goals. The right hydrometer can really help your syrup-making.

Investment Considerations and Cost Analysis

Buying a maple syrup production tool needs smart financial planning. Sugarmakers know that picking the right maple syrup harvesting kit is key to their success. It affects how well they make syrup and how much money they make.

Before buying a maple syrup hydrometer, producers must think about a few important money matters:

- Initial equipment costs

- Potential productivity improvements

- Long-term operational benefits

Initial Investment Breakdown

The price of a maple syrup tool changes a lot based on its tech level. Basic hydrometers cost between $50 and $200. But, top-notch digital ones can be over $500.

Long-term Value Considerations

Choosing a good hydrometer brings big benefits. Precise density measurements help sugarmakers:

- Reduce product waste

- Improve syrup quality consistency

- Optimize production processes

Return on Investment Strategy

Investing in top-notch syrup testing gear can really pay off. By picking the right hydrometer, producers can:

- Get better syrup grades

- Lower processing mistakes

- Get higher syrup prices

Conclusion

A maple syrup hydrometer is more than a tool for measuring. It’s key for making sure syrup quality is top-notch. Sugarmakers in the U.S. know that precise density tests are essential for making great syrup.

By using strict quality control, producers can take their syrup-making to the next level. A good hydrometer lets them check syrup density accurately. This helps avoid bad batches, cuts down on waste, and keeps the syrup industry’s good name.

Getting better at making maple syrup takes hard work and a love for precision. Producers who aim for excellence know that every syrup drop shows their commitment. With the right tools and skills, they can make syrup that people love and keeps the tradition alive.

Measuring syrup quality is not just about numbers. It’s about passion, skill, and honoring a craft that connects people across North America’s maple lands.